We are nearing completion on the installation of the IceTop tanks. Let's review the steps necessary to complete this year's IceTop goals:

- Prepare tanks for fill. James Roth serviced and double-checked all the freeze control units, their pumps and their electronics. Tom Gaisser, Chris Elliott, Bakhtiyar Ruzybayev, and I prepped the doors for the freeze control units, then installed the units. We cleaned out the tanks and attached a contactor to the inside of the tank.

Installing the FCU

Prepare DOMs for fill. We mounted the DOMs on sturdy hardware so we could hang them above the tank safely.

Opening a new DOM box for mounting.

This DOM is mounted on wood, later it will be hung up-side down in the tank. Wire everything together in the surface junction box and connect the surface cables to the computers in the IceCube Lab.

Working on the surface junction box. Get clean water for the fill. We use water from Drill camp but this can mean there is propylene glycol in the water, antifreeze leftover from last year. So we need to test the water for glycol and make sure that it is dilute enough (less than 10 parts per million ideally.)

Propylene glycol (antifreeze) test tubes. The darker the color, the more propylene glycol is present. Over time every tube will turn purple because the reaction will continues even past testing. That's how I know that the older tests are to the left in this photo.

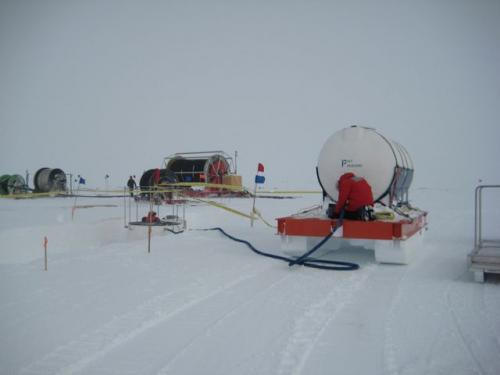

Fill the "water buffalo" and transport it to the tanks for filling.

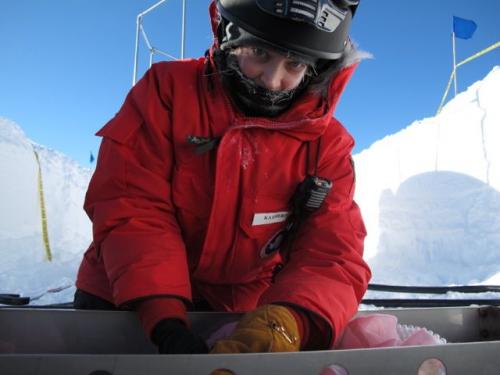

The water buffalo is attached to a tractor to take to the trench. Fill the tanks with liquid water and make sure all the electronics are working.

Filling the tank Let the water freeze. Initially with the lids closed so that the freezing starts slowly, later with the tank lids open but direct sun averted with sun shades. Over time when snow drifts into the tanks it must be cleared off so that freezing can continue-the thick snow would act like a blanket insulating the water so it wouldn't freeze as fast. During this time the freeze control unit pumps out excess gases that are trapped in semi-permeable membranes in the contactor in the tank. The sump pump regulates the water pressure in the tank as the ice expands and pushes water down so that it doesn't crack the ice.

James Roth and Tom Gaisser setup the sunshades. Once the water is frozen remove the sun shades and the freeze control units. Close the tank lids and dump snow back into the trench. Then the tank is ready to collect data for up to 20 years.

We only had 16 tanks to finish this year. Hopefully, they'll all be done by the end of this week.

Comments