Given the limited time I have remaining at McMurdo, it seemed wise to take a look at a few of the other work centers around the station. Today, I received three great tours of the Power, Water, and Wastewater plants.

Electricity

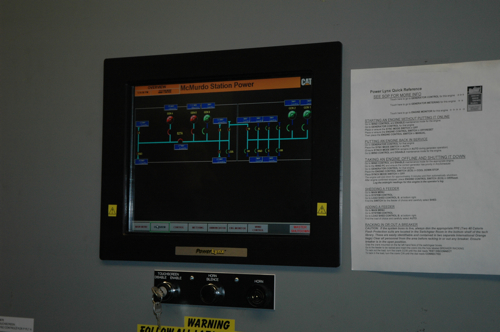

We rely on power for everything here in McMurdo - from lights to heat, conducting the science, to getting a hot shower. The Power Plant is an amazing place at McMurdo Station, and it runs 24 hours a day, 7 days a week, 365 days a year. As Chris (our fabulous tour guide) said, "If we're doing our job well, you never know we're hear. But when something goes wrong, everyone realizes how important we are." McMurdo Station uses a series of large diesel Caterpillar generators to provide power to every building on the station.

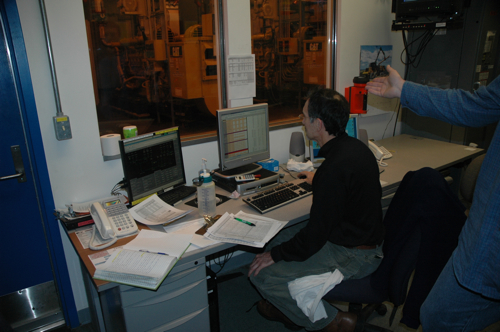

The generators are constantly running to provide ample power, and therefore a technician is always monitoring their performance. The entire power plant is built in duplicate, with two separate, redundant parts. If there is a problem on one side of the power plant, they can shut it done and switch to the other side. Both sides of the building can be remotely controlled from the other side.

Monitors, cameras, and sensors allow the technicians to keep an eye on every piece of equipment. There are whole rooms full of circuit breakers, switches, and generators. The beauty of the system is that if the generators stopped working, they can switch to the other side of the plant. The same is true for when maintenance needs to be done.

Another really cool part of the McMurdo Power system is that there are wind turbines tied in to the system providing electricity when the wind is spinning the turbines. Chris says there are currently three turbines, but there is the ability to expand. The wind turbines are making a noticeable difference to how frequently the generators need to run.

Water

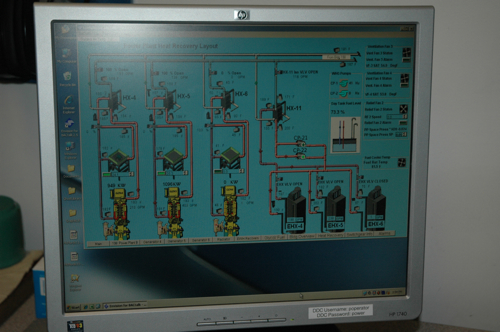

McMurdo Station must produce all the freshwater that is required for drinking. To do this, the station utilizes a process called reverse osmosis. Essentially, reverse osmosis uses sea water, pressure, and a series of membranes (filters) that remove the salt and other impurities from the water. In the end, you get fresh, clean drinking water.

The reverse osmosis requires careful monitoring and some chemistry. Usually, a couple of chemicals are added to keep the water bacteria free (like chlorine) and balance the pH.

However, that freshwater requires a lot of energy to create it. Therefore, we have been constantly reminded to conserve freshwater by limiting showers, laundry, and other tasks that involve freshwater. Chris informed us that the station has the ability to generate 40,000 gallons of freshwater in a day.

Wastewater Treatment

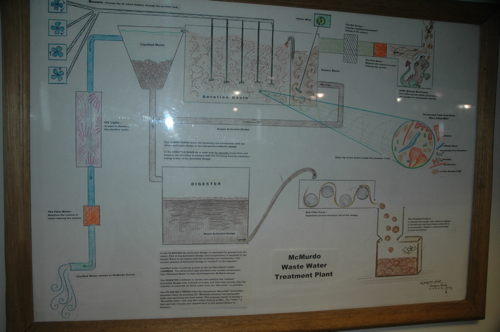

Another amazing part of McMurdo Station is the amazing lengths that we go to minimize our impact on the environment. That extends to our wastewater as well. The wastewater treatment plant handles all the water that goes down the drain, shower, or toilet. The basic idea behind wastewater treatment is to create an environment that encourages naturally occurring bacteria and other microbes to breakdown our waste back into raw nutrients. This involves a multi-stage process.

The first step is to grind up all the material coming into the wastewater treatment plant. This is done with a machine called a macerator. It mechanically breaks up all the material, making it much easier for the microbes to break it down.

Next, the material (called sewage) enters a tank filled with anaerobic microbes. These microbes break down the material and are very tolerant of problems and toxins. Then, the sewage moves to the aerobic microbes. These organisms are a major player in breaking down the material, but are not very tolerant of toxins. At this stage, the wastewater treatment plant begins separating the water from the solids. Finally, the sewage is passed to a digesting tank. Here microbes continue to breakdown the material. At this stage, we are really getting down to just the raw material nutrients that are mostly solids.

After the digesters, the material is passed to a belt press, which squeezes the majority of the water out, leaving a small box of solid that looks like potting soil. This is boxed up and shipped back to the United States.

The water that is left from all of this is basically drinkable freshwater, but just to be safe the water is treated with ultraviolet light, which kills the microbes, before pumping the water out to McMurdo Sound.

In short this wastewater treatment process is amazing! It doesn't even smell there (it seriously smells like potting soil), and is such a cool combination of chemistry and biology!

Summary

In short, I am so impressed by all three of these plants. I love that everything is set up to be as efficient as possible and that everyone takes their responsibility so seriously. Nothing is wasted. Even the heat energy that the generators produce is captured by a chemical called glycol, which is pumped to all the buildings around town, heating up the buildings!

I had three great tours! I wish I had time for even more. There are so many cool work centers around McMurdo!

Comments